VMC850B CNC Milling tshuab, ntsug tshuab chaw

Khoom nta

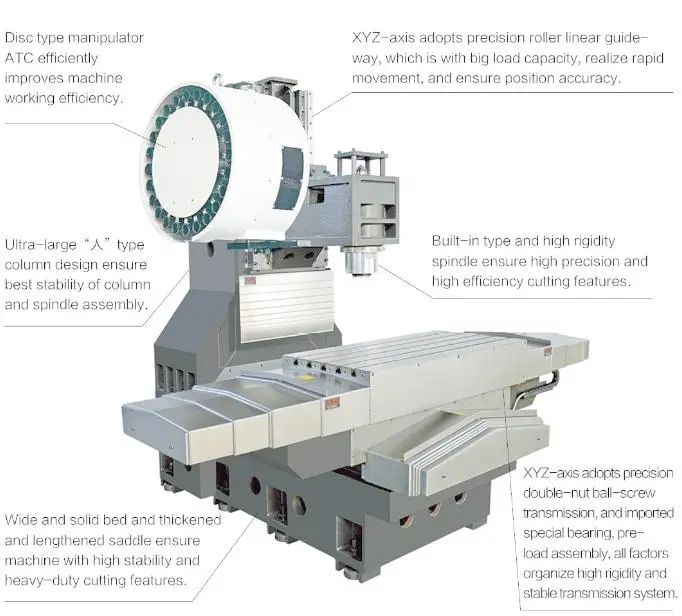

1.Kev qhia tag nrho

Lub tshuab no yog tsim los nrog ntsug ncej layout. Cov kem yog mounted rau ntawm lub tshuab lub cev, spindle lub thawv swb rau ntawm kem ua Z axis suab, eeb slides ntawm lub tshuab lub cev ua Y axis suab, Worktable slides ntawm lub eeb txoj kev X axis tsab ntawv tsa suab. Peb axes yog tag nrho cov kab ntawv qhia nrog kev pub noj ceev dua thiab siab dua. Peb siv cov khoom zoo grey cam khwb cia hlau rau tshuab lub cev, kem, eeb, worktable, spindle box nrog cob xuab zeb tshuab thiab 2 zaug aging kev kho mob kom tshem tawm cov residual kev nyuaj siab ntawm cov khoom. Cov khoom no yog txhua yam optimized los ntawm SolidWorks software, uas txhim kho ntau qhov rigidity thiab stability tsis yog rau cov khoom no xwb tab sis lub tshuab. Tsis tas li ntawd nws yuav txwv tsis pub deformation thiab kev vibration los ntawm kev txiav. Cov khoom tseem ceeb yog tag nrho cov khoom siv los ntawm lub ntiaj teb nto moo hom los ua lub tshuab nrog ntau dua stability thiab durability. Lub tshuab no tuaj yeem ua tiav cov txheej txheem ntawm milling, drilling, reaming, tho txawv, reaming, tapping thiab feem ntau yog siv rau Tub Rog, mining, automotive, pwm, instrumentation thiab lwm yam mechanical processing industries. Nws tuaj yeem siv rau txhua yam ntawm kev ua haujlwm siab thiab ntau cov qauv txheej txheem. Nws yog qhov zoo rau me me thiab nruab nrab, ntau ntau ntau lawm, thiab nws tuaj yeem muab tso rau hauv cov kab ntau lawm.

2.Peb axes system

Peb axes yog tag nrho cov kev taw qhia kab thiab nrog loj span tsim kom ruaj precision. Cov motors ntawm 3 axes yog txuas ncaj qha nrog high precision pob ntsia hlau los ntawm tsis muaj qhov sib txawv hloov tau yooj yim coupling. Txhua lub pob ntsia hlau ntawm 3 axes yog imported los ntawm precision angular hu rau pob ntsia hlau thiab cov bearings kev sib tw, kuj peb yuav ua ua ntej nro rau lub pob screws rau siab dua thiab precision.Z-axis servo lub cev muaj zog tsis siv neeg nres. Nyob rau hauv cov ntaub ntawv ntawm lub hwj chim tsis ua hauj lwm, lub cev muaj zog nres yuav cia li tuav los ntawm lub nres los tiv thaiv nws los ntawm rotating, uas plays lub luag hauj lwm nyob rau hauv kev tiv thaiv kev ruaj ntseg.

3.Spindle unit

Spindle yog tsim los ntawm cov chaw tsim khoom lag luam kom paub tseeb tias qhov siab thiab rigidity. Spindle bearing yog los ntawm lub ntiaj teb nto moo siab precision bearing hom, thiab sib sau ua ke ntawm qhov kub thiab txias thiab tsis muaj plua plav. Tom qab ntawd, tag nrho cov spindles yuav ua qhov kev ntsuam xyuas ntawm dynamic tshuav nyiaj li cas kom paub tseeb tias lub neej ncua thiab kev cia siab. lub spindle. Rau qhov xwm txheej no, cov kabmob spindle yuav ua haujlwm nyob rau hauv tsis muaj kuab paug ib puag ncig, uas yuav tiv thaiv lub spindle chav tsev thiab nrog lub neej ntev spindle. Spindle ceev yuav tsis muaj -step hloov nyob rau hauv lub spindle ceev ntau yam, uas yog tswj los ntawm lub cev muaj zog inner encode yuav tsum tau nrog lub functionality ntawm spindle orientation thiab nruj tapping.

4.Tool hloov qhov system

Tus txheej txheem cuab yeej magazine muaj peev xwm ntawm lub tshuab no yog 24T thiab sib sau ua ke ntawm sab sab. Thaum nws hloov cov cuab yeej, cov cuab yeej phaj tsav thiab muab tso rau ntawm lub cev muaj zog tsav hobbing cam mechanism, tom qab lub spindle tuaj txog ntawm txoj hauj lwm ntawm cov cuab yeej hloov, ATC yuav ua tiav cov cuab yeej hloov thiab xa cov cuab yeej ua haujlwm. ATC yog hobbing cam mechanism thiab ua ntej nro ces tuaj yeem ua haujlwm siab ceev, uas yog qhov zoo dua rau kev hloov pauv sai thiab raug.

5.Coolant system

Lub tshuab yog nruab nrog loj ntws upright immersion txias twj tso kua mis thiab loj muaj peev xwm dej tank. Lub twj tso kua mis txias ceev yog 2m³ / h kom paub tseeb tias qhov rov ua kom txias dua. Muaj cov cua txias nozzle rau ntawm qhov ntxaiv qhov kawg qhov chaw, uas tuaj yeem ua rau cua txias thiab dej txias rau cov cuab yeej thiab cov khoom ua haujlwm. Nruab nrog rab phom cua los ntxuav lub tshuab thiab ua haujlwm.

6.Pneumatic system

Pneumatic chav tsev tuaj yeem lim cov impurities thiab noo noo hauv cov pa roj kom tsis txhob muaj kev puas tsuaj thiab yaig ntawm lub tshuab qhov chaw. Solenoid valve chav tswj qhov kev pab cuam los ntawm PLC kom paub tseeb tias cov kev ua ntawm spindle unclamping cuab tam, spindle center tshuab, spindle clamping cuab tam thiab spindle cua coolant tuaj yeem ua tau sai thiab raug. Txhua lub sij hawm spindle hloov cuab yeej, cov huab cua ntshiab yuav tshuab los ntawm qhov chaw spindle los ntxuav lub ntxaiv puab lub qhov thiab cov cuab yeej shank rau siab rigidity ntawm kev sib xyaw nrog spindle thiab cov cuab yeej. Nws yuav nthuav lub neej spindle.

7. Tshuab kev tiv thaiv

Peb siv cov qauv kev tiv thaiv kev nyab xeeb rau lub tshuab, uas tuaj yeem tsis tsuas yog tiv thaiv cov dej txias txias tab sis kev nyab xeeb kev ua haujlwm. Txhua txoj kev taw qhia yog nruab nrog cov ntaub thaiv npog tiv thaiv kom tsis txhob muaj cov dej txias thiab txiav rau hauv qhov chaw sab hauv thiab txo qis kev hnav thiab yaig ntawm kev taw qhia thiab pob ntsia hlau.

8.Lubrication system

Kev taw qhia thiab lub pob ntsia hlau tau nruab nrog lub hauv nruab nrab lubrication system thiab nrog cov roj ntim roj cais hauv Txhua lub ntawm, uas tuaj yeem muab cov roj ntawm cov khoom ruaj khov thiab lub sijhawm kom paub tseeb tias txhua lub ntsej muag lub ntsej muag lubricated thiab qis dua fabrication. Nws yuav txhim kho qhov tseeb thiab lub neej ntev ntawm lub pob ntsia hlau thiab cov lus qhia.

9.Chip conveyor system

Peb muab cov txheej txheem phau ntawv nti tshem tawm cov cuab yeej nrog kev ua haujlwm yooj yim. Tsis tas li koj tuaj yeem xaiv cov ntsia hlau hom nti conveyor lossis pob khawm hom.

| Yam khoom | Chav tsev | wb 640l | VMC 640 LH | VMC850L | VMC 1000L |

| Lub rooj ua haujlwm | |||||

| Worktable loj | mm | 400 × 900 hli | 400 × 900 hli | 500 × 1000 hli | 500 × 1200 hli |

| T-qhov (N × W × D) | mm | 3 × 18 × 100 | 3 × 18 × 100 | 5 × 18 × 100 | 5 × 18 × 100 |

| Mus ncig | |||||

| X axis taug kev | mm | 640 | 640 | 850 | 1000 |

| Y axis taug kev | mm | 400 | 400 | 500 | 500 |

| Z axis taug kev | mm | 400 | 500 | 600 | 600 |

| Machining ntau | |||||

| Kev ncua deb ntawm spindle center mus rau sab pem hauv ntej | mm | 440 | 476 ib | 572 ib | 572 ib |

| Kev ncua deb ntawm spindle kawg mus rau lub rooj ua haujlwm | mm | 120-520 : kuv | 120-620 : kuv | 120-720 : kuv | 120-720 : kuv |

| Tshuab dimension | |||||

| L × W × H | mm | 2200 × 2100 × 2500 hli | 2200 × 2100 × 2550 | 2540 × 2320 × 2780 hli | 3080 × 2320 × 2780 hli |

| Tshuab hnyav | |||||

| Max. load bearing ntawm worktable | kg | 350 | 350 | 500 | 600 |

| Tshuab hnyav | kg | 3900 ib | 4 100 | 5 200 | 5600 ib |

| Spindle | |||||

| Spindle qhov taper | BT40 | BT40 | BT40 | BT40 | |

| Spindle zog | kw | 5.5 | 5.5 | 7.5/11 | 7.5/11 |

| Max. spindle ceev | rpm ua | 8000/10000 | 8000/10000 | 8000/10000 | 8000/10000 |

| Pub (direct drive) | |||||

| Max. pub ceev | mm / min | 10000 | 12000 | 12000 | 12000 |

| Kev ceev ceev ceev (X / Y / Z) | m/min | 20/20/10 | 30/30/24 IB | 32.32.30 Nws | 32.32.30 Nws |

| Pob ntsia hlau (inch + lead) | |||||

| X axis pob ntsia hlau | 3 210 | 3212 ib | 4 016 | 4 016 | |

| Y axis pob ntsia hlau | 3 210 | 3212 ib | 4 016 | 4 016 | |

| Z axis pob ntsia hlau | 3 210 | 4012 ib | 4 016 | 4 016 | |

| Tool Magazine | |||||

| Cov cuab yeej magazine muaj peev xwm | T | 16 | 16 | 24 | 24 |

| Lub sijhawm hloov cuab yeej | s | 2.5 | 2.5 | 2.5 | 2.5 |

| Positioning raug (National standard) | |||||

| Positioning raug (X/Y/Z) | mm | 0.008 ib | 0.008 ib | 0.008 ib | 0.008 ib |

| Re-positioning raug (X / Y / Z) | mm | 0.005 ib | 0.005 ib | 0.005 ib | 0.005 ib |

| TSIS MUAJ. | Lub npe | Hom |

| 1 | CNC system | Seimens 808D SYSTEM |

| 2 | Main lub cev muaj zog | Tag nrho cov txheej txheem ntawm Siemens tsav nrog rau servo lub cev muaj zog |

| 3 | X / Y / Z axis lub cev muaj zog, tsav tsheb | Seimens |

| 4 | Ballscrew | Hiwin los yog PMI (Taiwan) |

| 5 | Ballscrew bearing | NSK (Nyiv) |

| 6 | Linear qhia | Hiwin los yog PMI (Taiwan) |

| 7 | Spindle lub cev muaj zog | POSA/ROYAL (Taiwan) |

| 8 | Thaum tshav kub kub exchanger | Taipin/Tongfei (Joint-venture) |

| 9 | Lubrication system tseem ceeb Cheebtsam | Proton (kev sib koom tes) |

| 10 | Pneumatic system tseem ceeb Cheebtsam | AirTAC (Taiwan) |

| 11 | Hluav taws xob system lub ntsiab Cheebtsam | Schneider (Fabkis) |

| 12 | Lub tshuab nqus dej | Tuam Tshoj |